What is a Jewelry Box Cylinder Hinge?

A jewelry box cylinder hinge is a discreet yet robust cylindrical-shaped hardware component designed to seamlessly connect the box lid and body. Unlike traditional exposed butt or surface hinges, cylinder hinges are installed inside pre-drilled holes in the wood, remaining hidden and giving your jewelry box a premium, minimalistic, and tamper-resistant appearance.

Cylinder hinges are the gold standard for luxury and handmade jewelry boxes, due to their invisible mounting, smooth operation, and elegant feel. They’re favored by cabinet makers, DIYers, and jewelry packaging manufacturers who want both reliability and aesthetic excellence.

Key Features & Structure

A jewelry box cylinder hinge consists of:

-

Cylindrical “Barrel” Body:

Precision-machined metal, available in various diameters (commonly 4–10mm), fitted into drilled holes on both lid and box body.

-

Central Pivot Pin:

A hardened steel or brass pin through the axis, allowing smooth and durable rotational movement.

-

Friction/Press Fit:

Most models insert snugly into the wood for a secure, clean install; additional small set screws or glue may be used for more strength.

-

Optional Spring Mechanism:

Some cylinder hinges have internal springs, giving automatic open, close, or even soft-close action.

-

Nearly Invisible After Install:

Only the end of the hinge barrel might appear on the inside or side seam—exterior box surfaces remain flawless.

Types of Jewelry Box Cylinder Hinges

-

Standard (Non-spring) Cylinder Hinges:

The classic design, providing smooth, frictionless pivot; best for lightweight and medium jewelry boxes.

-

Spring-Loaded Cylinder Hinges:

With internal springs for self-opening (“pop-up”) or self-closing lids—great for single-handed operation and extra safety.

-

Heavy-Duty Barrel Hinges:

Thicker barrels and pivots for large or multi-compartment jewelry chests.

-

Decorative-End Cylinder Hinges:

Feature visible, shaped, or engraved ends for designer projects that want a tasteful ‘reveal’.

-

Micro Cylinder Hinges for Mini Boxes:

Tiny diameters (2–4mm) for ring boxes and delicate jewelry packaging.

-

Custom or Adjustable Tension Hinges:

Enable lid resistance/spring force tuning to match box weight and user preference.

Main Materials & Surface Finishes

A. Metals:

-

Solid Brass:

Corrosion-resistant, ages beautifully, suitable for fine woodworking and classic aesthetics.

-

Stainless Steel:

Ultra-durable, antirust, for modern, heavy-use, or humid environments.

-

Zinc Alloy:

Economical, perfect for mass production or gift packaging.

-

Nickel/Copper/Chrome Plated Brass:

For various color and style options.

B. Finishes:

-

Polished Brass

-

Satin Brass

-

Antique Brass/Bronze

-

Satin Nickel

-

Black Oxide / Matte Black

-

Chrome / Gold / Rose Gold

-

Powder-coating or custom colors by request

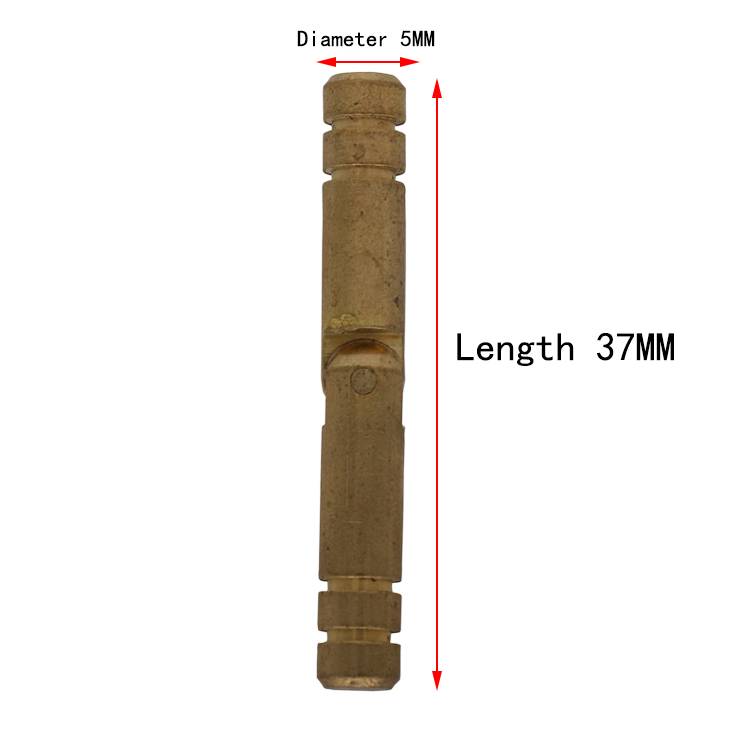

Standard Sizes & Technical Specs

|

Diameter

|

Length

|

Ideal Lid Thickness

|

Material

|

Finish Options

|

Weight Load*

|

|

4mm

|

10–15 mm

|

7–10 mm

|

Brass/Stainless

|

Polished, Nickel, Gold

|

~0.5kg

|

|

6mm

|

12–18 mm

|

9–12 mm

|

Brass/Stainless

|

Satin, Black, Chrome

|

~1kg

|

|

8mm

|

16–25 mm

|

11–16 mm

|

Brass/Stainless

|

Antique, Silver, Gold

|

~1.5kg

|

|

10mm

|

20–30 mm

|

13–19 mm

|

Brass/Stainless

|

Custom

|

2kg+

|

*Per pair, varies by hinge quality and box design.

Advantages of Cylinder Hinges for Jewelry Boxes

-

Invisible, Sleek Look:

No visible hardware on the box exterior—showcases only premium wood or inlay.

-

Safe & Tamper-Proof:

No exposed screws to pry or tamper with—perfect for heirlooms or gifts.

-

Smooth, Long-Lasting Operation:

Metal pivots resist wear, provide decades of easy opening and closing.

-

Maximum Space Efficiency:

Hinges don’t cut into box interior or exterior space; ideal for tight and compact designs.

-

Professional and Luxurious Feel:

Instantly upgrades the user experience, perceived value, and tactile quality of your jewelry box.

-

Customizable:

Choose size, finish, profile, and spring action to perfectly suit your project.

Jewelry Box Designs & Applications

-

Luxury Jewelry Boxes:

Designed for necklaces, rings, earrings—adds the final touch to custom or branded packaging.

-

Wooden Gift Boxes & Keepsake Chests:

For special occasions (weddings, anniversaries, graduations) where aesthetics and security matter.

-

Watch Boxes and Presentation Cases:

Where smooth lift and secure closure are vital.

-

Coin and Medal Display Boxes:

For collectors and memorabilia.

-

Boutique or Custom Packaging:

For designer jewelry retailers and unique handmade pieces.

-

Fine Pen, Mini Wine, or Perfume Boxes:

Any compact wooden or composite box needing an elegant hidden hinge solution.

Cylinder Hinges vs. Other Box Hinges

|

Attribute

|

Cylinder Hinge

|

Butt Hinge

|

Barrel Hinge

|

Piano Hinge

|

|

Visibility

|

Hidden/Minimal

|

Visible/Semi-hidden

|

Often partly visible

|

Fully visible

|

|

Installation

|

Requires drilling

|

Surface or mortise

|

Drill-in/slot cut

|

Full box edge mount

|

|

Space Efficiency

|

High

|

Medium

|

High

|

Low (covers length)

|

|

Security

|

Excellent

|

Good

|

Good

|

Basic

|

|

Price

|

Moderate to Premium

|

Economic

|

Moderate

|

Economic to Modest

|

|

Typical Finish

|

Various metals

|

Brass/nickel/zinc

|

Brass/stainless/steel

|

Brass/steel

|

|

Target Application

|

Premium/DIY/modern

|

Utility, economy

|

Premium/traditional

|

Utility, large boxes

|

How to Choose the Right Cylinder Hinge for Your Jewelry Box

-

Box Size and Lid Weight:

-

Small boxes & ring boxes: 4–6mm diameter hinge, short length.

-

Medium jewelry boxes: 6–8mm, medium length.

-

Large or heavy chests: 8–10mm, longer length, potentially three hinges.

-

Wood Thickness:

-

Hinge length should be slightly less than wood thickness for invisible installation.

-

Material & Finish:

-

Match the hardware/locks (classic: polished or antique brass; modern: nickel/black/gold).

-

Stainless steel for humid or frequently handled boxes.

-

Spring or Non-spring:

-

Choose spring-loaded for automatic/self-closing and safety, non-spring for light, classic-style boxes.

-

Use a drill bit matching the barrel's diameter. Depth equals hinge length. Use a stop collar and drill press for accuracy.

Step 3: Test-fit and Align Hinges

Dry fit for alignment. The hinge should sit flush, and the lid must line up with the box body before full installation.

Step 4: Secure Hinges

Press-fit is standard. For added security, apply a tiny amount of glue (never on pivot). For heavy-duty types, use small set screws.

Step 5: Test Lid Action

Fit the lid and test for light, even swing and no wood binding.

Pro Tips:

-

Use a jig/guide for consistent drill angles.

-

For high-gloss or soft woods, use tape to prevent splintering.

Care & Maintenance

-

Wipe occasionally with soft cloth to avoid debris buildup around the pivot point.

-

Lubricate with a single drop of light oil on the hinge pivot every 1–2 years if operation stiffens.

-

Check for fit annually in high-use boxes; fix any looseness with wood-safe adhesive.

-

Do not force open/closed against hinge's designed rotation—could cause premature wear.

Customization and OEM/ODM Services

-

Custom diameters/lengths to fit unique jewelry box designs.

-

Material and surface selection for brand-matching and environmental compliance.

-

Logo or model engraving on hardware for anti-counterfeiting or luxury branding.

-

Spring tension tuning for tailored lid action.

-

Bulk supply, retail packaging, and dropship options for brands and large makers.

-

Full compliance with RoHS, REACH and other international standards.

Industry Trends

-

Micro Cylinder Hinges:

Growing demand for micro/mini hinges for compact and elegant jewelry packaging.

-

Soft-close technology:

Integration of slow/soft-close spring mechanisms in luxury box hardware.

-

Sustainable & hypoallergenic materials:

More box makers are requesting eco-friendly hinges and allergy-safe alloys.

-

Brand customization:

Unprecedented attention to hinge color, finish, and laser logo engraving for brand identity.

-

Invisible magnetic/smart cylinder hinges:

R&D is bringing anti-bounce, RFID, or magnetic integration for “smart” jewelry packaging.

SEO Keywords

Jewelry box cylinder hinge, cylinder hinge for jewelry box, hidden box hinge, round barrel hinge, concealed jewelry box hinge, brass cylinder hinge, spring loaded cylinder hinge, luxury box hinge, mini cylinder hinge, micro jewelry box hinge, invisible hinge for box, custom jewelry box hinge, OEM jewelry box cylinder hardware, stainless cylinder hinge, decorative jewelry hinge, premium jewelry box hardware, barrel box hinge, soft-close jewelry hinge.

Why Choose Us

-

Precision manufacturing:

Decades of experience serving global jewelry and luxury box brands.

-

Guaranteed authentic materials:

Solid brass, stainless steel, and verified alloys only.

-

Industry-leading customization:

Any size, color, finish, logo, or packing option for your box or brand.

-

Sample to bulk delivery:

Fast sample turns, flexible MOQs, drop shipping and global logistics.

-

Strict quality control:

100% QC for all hardware. Full refund or replacement provided for rare defects.

-

Expert support:

Multi-lingual sales, CAD drawing, and technical guidance on any hinge problem.

Get a Free Sample or Custom Quote

Ready to elevate your next jewelry box with a world-class cylinder hinge?

Contact our team now for detailed catalogs, free samples, technical specs, bulk quotations and OEM/ODM service. We help you create flawless jewelry, gift, and keepsake packaging—every lid, every time.

Additional Information

1. Packaging & Export Logistics

Our jewelry box cylinder hinges are carefully packed with anti-scratch paper, foam, or polybags, then boxed for domestic and international shipping. For bulk orders, we offer custom packaging with your logo or retail-ready boxes. All shipments are inspected before dispatch and packed to minimize transit damage.

2. Minimum Order Quantity (MOQ) and Samples

Small MOQs are supported for designers, crafters, and prototyping. For standard models, MOQ is as low as 50–100 sets. Free samples or mixed sample packs are available—contact us for details.

3. Quality Control

Every batch undergoes a strict QC workflow, including material verification, dimensional checks, surface finish inspection, and function testing. Our facility follows ISO9001 standards and can provide third-party inspection reports on request.

4. Shipping & Lead Time

Fast dispatch of in-stock products worldwide. Custom or OEM orders generally ship within 10–25 days, depending on complexity and finish. We support express (DHL, FedEx), air, and sea freight, always with tracking.

5. Engineering Support

We offer free technical drawings, CAD installation files, and drilling templates to simplify your design or assembly process. Our technical team is always available for consultation on unusual materials, hole layouts, or specific box constructions.

6. Sustainability Commitment

We provide RoHS, REACH, and lead-free compliant cylinder hinges and finishes. Packaging uses recyclable or compostable materials wherever possible. We encourage resource-efficient, long-lifetime design.

7. After-Sales Service

All products are covered by our quality warranty. In the rare case of defects or mismatches, we offer immediate free replacement or refund, and rapid troubleshooting support.

8. Documentation & Certificates

Material certificates (SGS, MSDS), surface treatment records, and compliance documents available for large/bulk orders or sensitive export destinations.

9. Flexible Solutions

Whether you need coordinated box locks, magnets, decorative hardware, or complete gift box kits—we provide one-stop sourcing and matching sets.

10. Global Experience

Our partners include luxury brand packaging houses, jewelry box factories, furniture workshops, online craft sellers, and professional designers in over 50 countries.

Frequently Asked Questions (FAQ)

Q1: How many hinges does a jewelry box need?

A: Two are standard. For wide or heavy box lids, use three for even support.

Q2: Are cylinder hinges reusable?

A: Yes, if removed intact during box refurbishing. Avoid damaging the barrel or pivot.

Q3: Can I use these on MDF, particleboard, or plywood?

A: Yes, if the thickness accommodates the chosen hinge. Check for chipping around drilled holes.

Q4: Can hinges be seen when the box is closed?

A: Not if correctly sized and fitted; only the seam/gap is visible.

Q5: Do you offer sample packs for craftspeople or brands?

A: Absolutely. Free and paid sample packs available for evaluation.

Q6: Are spring tension and length customizable?

A: Yes, for OEM or bulk orders, we can manufacture to specific requirements.

Q7: What are the minimum panel thicknesses for installation?

A: Ideally 1mm–2mm more than the hinge barrel's length; usually 8mm+ for best results.

Q8: Are your hinges RoHS and REACH compliant?

A: Yes, all finishes and materials available with environmental and safety certifications.