Metal Cylindrical Hinge for Wooden Boxes: The Complete and Definitive Guide

Overview: What is a Metal Cylindrical Hinge?

A metal cylindrical hinge is a compact, robust, and aesthetically discreet hardware component designed to connect and pivot two sections of a box or cabinet—typically the lid and body—using a cylindrical, barrel-like form that is embedded within the wood itself. Because of its design, once installed, much of the hinge is hidden inside pre-drilled holes, leaving a nearly invisible, streamlined appearance from the outside.

These hinges are fabricated from durable metals—such as brass, stainless steel, or zinc alloy—and are highly favored wherever seamless design, security, and long-term reliability are priorities.

Main Structural Features

-

Cylindrical Barrel:

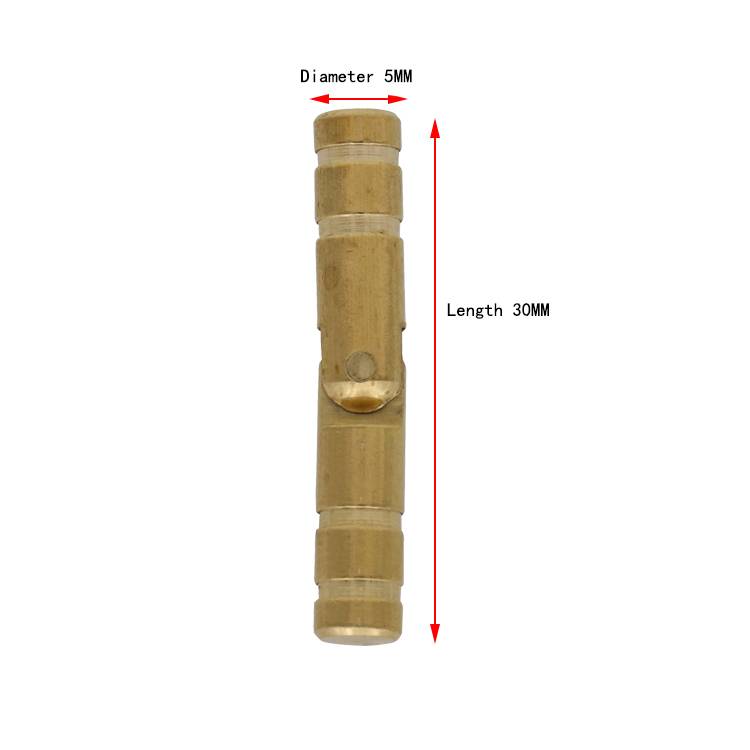

The defining feature—a precision-machined round shaft, typically ranging from 4mm to 14mm in diameter, accommodates the box’s material and weight.

-

Central Pivot Pin:

A metal pin (often brass or stainless steel) runs through the barrel, enabling effortless rotation and long-term durability.

-

Insertion Limbs/Ends:

Short tangs, studs, or knurled ends ensure secure fixation inside the drilled hole.

-

Surface Treatment:

Finishes such as polished, satin, antique, blackened, or specially coated, providing design flexibility and corrosion resistance.

-

Optional Spring Mechanism:

Some versions feature spring-loaded operation for automatic opening or self-closing function.

Types of Metal Cylindrical Hinges

1. Classic Cylindrical Barrel Hinge

Standard precision barrel, perfect for decorative and luxury boxes; no extra mechanisms, simply a smooth, reliable pivot.

2. Concealed Cylindrical (Invisible) Hinge

Engineered to remain completely hidden once installed—ideal for minimalist and modern projects.

3. Spring-Loaded Metal Cylindrical Hinge

Incorporates an internal spring, offering self-opening, self-closing, or even soft-close movement, used for premium jewelry boxes or instrument cases.

4. Heavy-Duty or Oversized Cylinder Hinge

For large or weighty lids, often made from thick brass or stainless steel, with enhanced load-bearing pivots.

5. Decorative Metal Barrel Hinge

Features engraved barrels or colored/ornate endcaps, increasing visible appeal where part of the hinge may be left exposed.

Standard Sizes and Finishes

|

Diameter

|

Length (mm)

|

Typical Finish

|

Recommended Box Thickness

|

|

4mm

|

10–12

|

Brass, Nickel, Black

|

7–10mm

|

|

6mm

|

12–20

|

Brass, Gold, Chrome

|

10–14mm

|

|

8mm

|

16–30

|

Stainless, Antique

|

12–20mm

|

|

10mm

|

20–35

|

Polished, Satin Black

|

15–25mm

|

|

12-14mm

|

30–40

|

Custom Plating

|

18–28mm

|

Popular Surfaces:

-

High-Polished Brass

-

Antique or Aged Brass

-

Satin Nickel or Chrome

-

Black Anodized/Plated

-

Gold, Rose Gold

-

Custom Colors (OEM/brand order)

Advantages for Wooden Box Applications

-

Seamless Visual Presentation

-

Virtually hidden hardware preserves the clean lines and surface beauty of fine woods.

-

Space Efficiency

-

Compact design enables maximum use of box interior space.

-

Enhanced Security

-

No visible screws or plates to tamper with—ideal for valuable item storage.

-

Versatile Compatibility

-

Suitable for a range of woods (hard/soft), as well as plywood, MDF, and even some plastics.

-

Superior Durability

-

Precision metal design and quality pivot ensure thousands of silent, frictionless cycles.

-

Brand Value Enhancement

-

Makes any jewelry, gift, or presentation box feel genuinely “handmade” and high-class.

Typical Applications

-

Luxury Jewelry Boxes & Watch Cases

-

Keepsake/Memoir Chests

-

Tea, Wine, and Cigar Boxes

-

Decorative Display Cases

-

Musical Instrument & Camera Cases

-

Premium Packaging for Pens, Coins, Medals

-

Craft, DIY, Artisanal Gift Boxes

-

Secret Compartments & Hidden Drawers

-

Custom Cabinets & Small Furniture

Comparison With Other Hinges

|

Attribute

|

Metal Cylindrical Hinge

|

Butt Hinge

|

Piano/Continuous Hinge

|

Concealed "Euro" Hinge

|

|

Visibility

|

Hidden

|

Partly/exposed

|

Fully exposed

|

Hidden, but large

|

|

Mounting Position

|

Internal/flush

|

External/surface

|

Surface/mortised

|

Mortised/EU furniture

|

|

Application

|

Premium boxes, crafts

|

Utility & basic box

|

Large utility boxes

|

Kitchen/furniture

|

|

Load Bearing

|

High (size dependent)

|

Medium

|

High

|

High (not for boxes)

|

|

Aesthetic Value

|

Highest/minimalist

|

Moderate

|

Low

|

Moderate

|

|

Security

|

Excellent

|

Fair

|

Fair

|

High

|

Selection Tips and Use Cases

-

Box Dimensions & Weight

-

For small/light lids: 4–6mm barrels.

-

For medium: 6–10mm.

-

For heavy/large: 10–14mm, or more hinges per lid.

-

Wood Thickness

-

Barrel length should match (or just under) the wood's thickness.

-

Avoid drilling through the box side.

-

Design & Finish Coordination

-

Polished/antique brass for classic designs.

-

Customization & OEM Services

-

Custom Diameter/Length

Tailor hinge size to project needs.

-

Material Selection

Brass, stainless steel, zinc alloy, and more.

-

Plating/Finishing

Match your box style or brand theme.

-

Spring-Load/Soft-Close Option

Internal springs for premium market appeal.

-

Logo Laser Engraving

For branding or anti-counterfeiting.

-

Bulk & Retail Packaging

Polybag, boxed kits, or factory packs.

-

RoHS/REACH & Sustainability

All finishes and materials available in eco-friendly versions.

Installation Guide

1. Mark the Hinge Points

-

Typically 10–30mm in from each lid end.

-

Use a ruler/marking template for accuracy.

2. Drill the Holes

-

Match drill bit to hinge diameter; depth = hinge length.

-

Use a drill press or guide for precise vertical holes.

3. Dry Fit Hinges

-

Insert the hinge lightly, test lid alignment and swing.

4. Secure the Hinges

-

Press fit is standard. For extra hold: add wood glue outside barrel (not on pivot/spring), or use set screws if provided.

5. Final Assembly and Test

-

Press fully in place.

-

Open and close lid to check for smooth, even movement.

Pro Tip:

-

For best results, use a drill stop or depth collar to avoid overdrilling.

-

Check and correct drill bit perpendicularity for smooth hinge action.

Maintenance and Care

-

General Maintenance

Wipe with a dry cloth; keep pivot clean.

-

Lubrication

One drop of light machine oil every few years on the pivot for ultra-smooth performance.

-

Avoid Overload

Do not force the lid against the hinge direction; over-tension may damage the mechanism.

-

Annual Check

For high-use boxes, inspect hinge snugness and adjust as needed.

Industry Trends

-

Miniaturization

Precision micro-sized barrel hinges for tiny jewelry and pill boxes.

-

Soft/Slow-Close Technologies

Advanced spring- or damper-integrated cylindrical hinges increasingly popular in high-end packaging.

-

Eco Materials & Finishes

Growing demand for RoHS/REACH-compliant, lead-free, and recyclable hardware.

-

Creative/Decorative Designs

OEMs offer colored, laser-engraved, and designer signature endcaps for branding.

-

Smart Integration

Magnetic, RFID, or electronic lock integration for innovative luxury boxes.

SEO Keywords—Naturally Used

Metal cylindrical hinge, cylindrical barrel hinge, concealed metal box hinge, metal invisible box hinge, round barrel hinge, jewelry box cylindrical hinge, spring-loaded cylindrical hinge, brass cylindrical hinge, stainless steel cylindrical hinge, invisible box hardware, hidden barrel hinge, premium box hinge supplier, decorative cylinder hinge, wooden box hardware, OEM metal hinge, custom metal barrel hinge, cylindrical box hinge manufacturer.

Technical Specifications Table (Typical Example)

|

Parameter

|

Value/Range

|

|

Material

|

Brass, Stainless Steel, Zinc

|

|

Barrel Diameter

|

4 / 6 / 8 / 10 / 12 / 14 mm

|

|

Barrel Length

|

10–40 mm

|

|

Surface Finish

|

Polished, Antique, Black, Gold

|

|

Pivot Pin

|

Brass/Stainless

|

|

Spring Option

|

Yes or No

|

|

Max. Load (2 pcs)

|

0.5–3 kg (depends on size)

|

|

Operating Angle

|

90°–180°

|

|

Installation

|

Press/glue fit, set screws

|

|

Life Cycle

|

20,000+ opens

|

|

Compliance

|

RoHS/REACH

|

|

Application

|

Box lid, drawers, furniture

|

Why Choose Us

-

Specialist in Box Hardware Solutions

Serving leading jewelry and gift box brands worldwide.

-

Material Assurance

Genuine brass, premium stainless steel, and reliable zinc alloys only.

-

End-to-End Service

In-house design, prototyping, mass production, and after-sales support.

-

Factory Direct, Customizable

Rapid sampling, flexible MOQ, and exclusive design support.

-

Quality Guarantee

Strict QC process; replacements or refunds on rare defective pieces.

-

Multi-Lingual, Fast Response

Fluent English service, with technical advice and efficient quote turn around.

Get a Quote or Sample

Ready to upgrade your next wood box project with world-class metal cylindrical hinge solutions?

Contact us now for free samples, catalogs, OEM/ODM requirements, technical support, and best-price quotes. See how seamless, sturdy, and beautiful your wooden boxes can be—with the right cylindrical hardware!

Frequently Asked Questions (FAQ)

Q1: Are metal cylindrical hinges suitable for thin plywood?

A: Yes, if the wood’s thickness matches or slightly exceeds the hinge’s barrel length.

Q2: How many hinges per box lid?

A: Two are standard for most sizes; wide/heavy lids warrant three.

Q3: Can I install these in MDF or plastic boxes?

A: Yes, provided the drill holes are accurate, and the material is at least as thick as the hinge.

Q4: Are spring-loaded cylindrical hinges adjustable?

A: Some types allow tension adjustment; many are factory-set—specify when ordering.

Q5: Do you offer different metallic finishes?

A: Yes, numerous finishes (polished, antique, black, gold, etc.) and even custom colors are available.

Q6: Is there a risk of barrel hinge showing outside the box?

A: Not if installed correctly. Select a barrel length under panel thickness to keep it invisible.

Q7: Can I get OEM sizes/logo?

A: Absolutely—OEM/ODM services for custom size, engraving, packaging, and finishes.

Q8: Are these durable for heavy-use applications?

A: Brass and stainless steel types withstand tens of thousands of cycles without made-in-China: fatigue.